Electronics

Overview

The Electronics Department, which includes sub-departments such as Software and Control Systems, is in charge of the design, production and testing of all the on-board and ground electronic systems. These include the rocket’s control software, the telemetry systems, and the data transmission systems. Everything is designed and tested internally, from the operating system to the specs and schematics of every board. We mostly rely on our kind sponsors for the production phase, though we sometimes have to come up with creative solutions such as DIY photolithography and the soldering of singular components to complete the more intricate parts of our projects.

Preliminary Circuit design

The main role of the ELC sub department is to produce the rocket’s avionics. To complete our task we begin with discussing new solutions and components for our circuits, to then complete a feasibility study and some preliminary pen and paper design in order to start assessing the component values, as well as a few computer simulations.

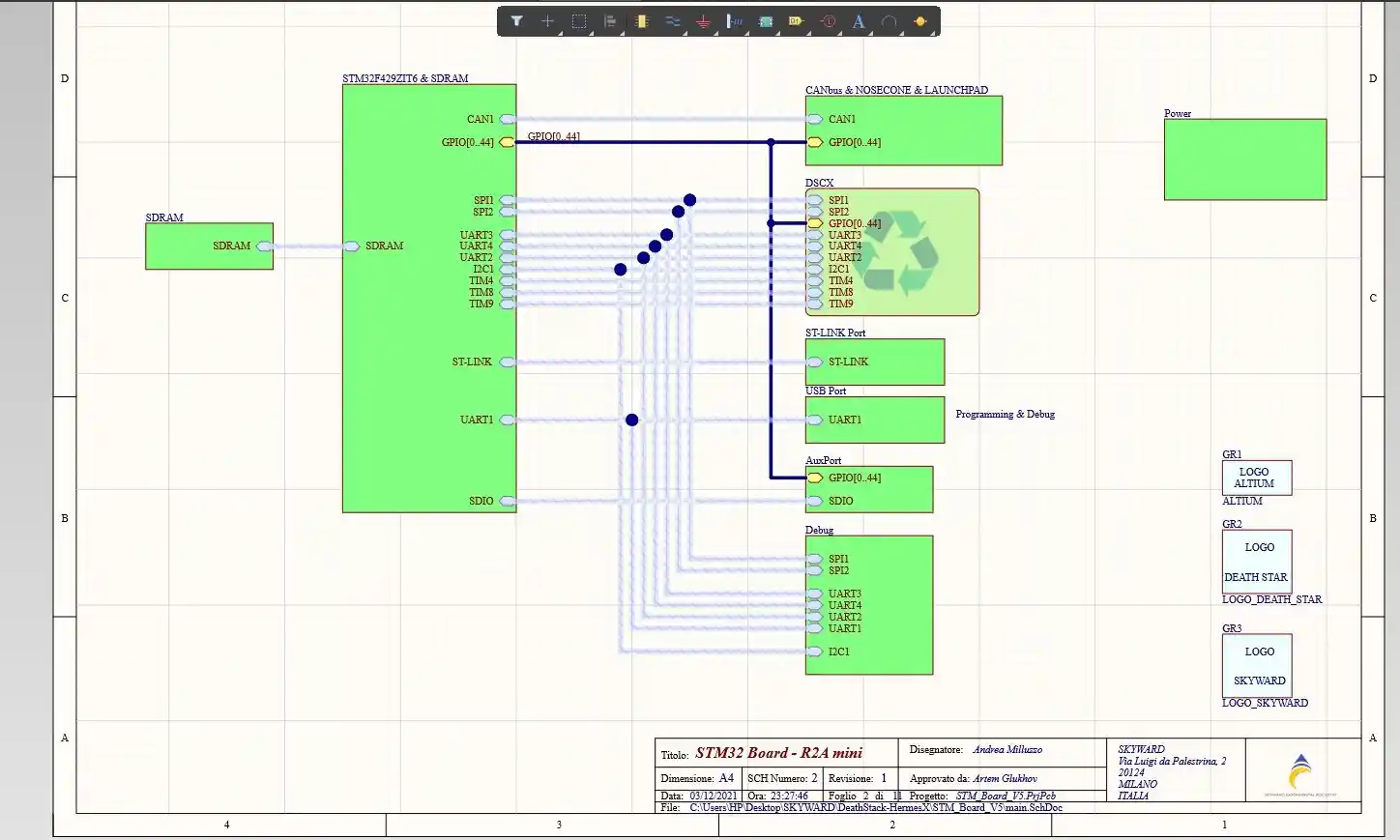

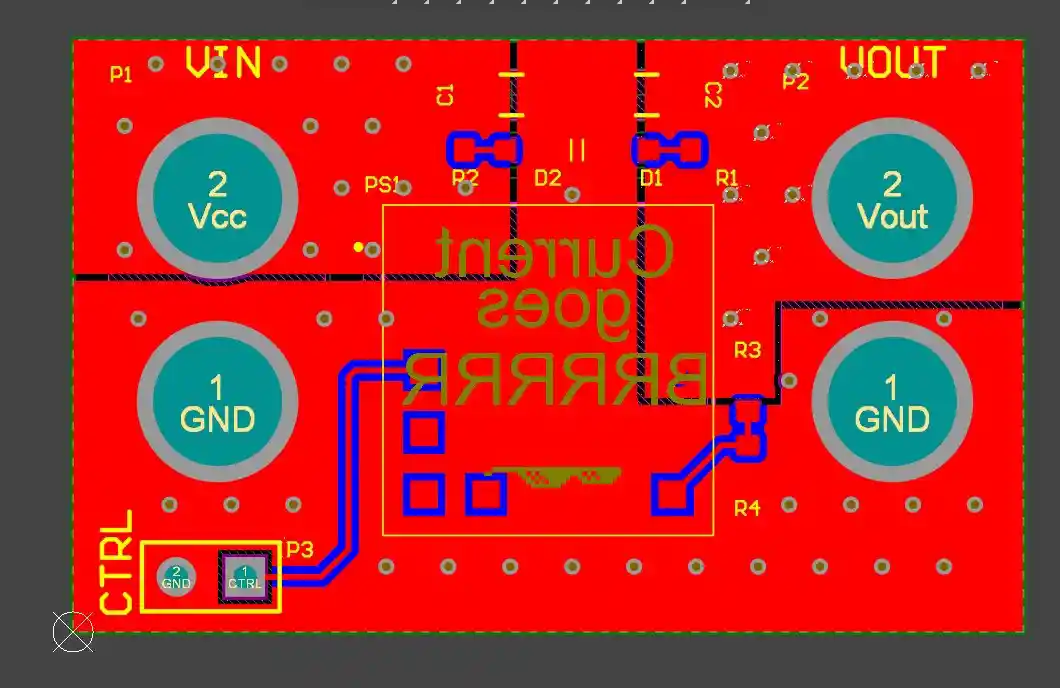

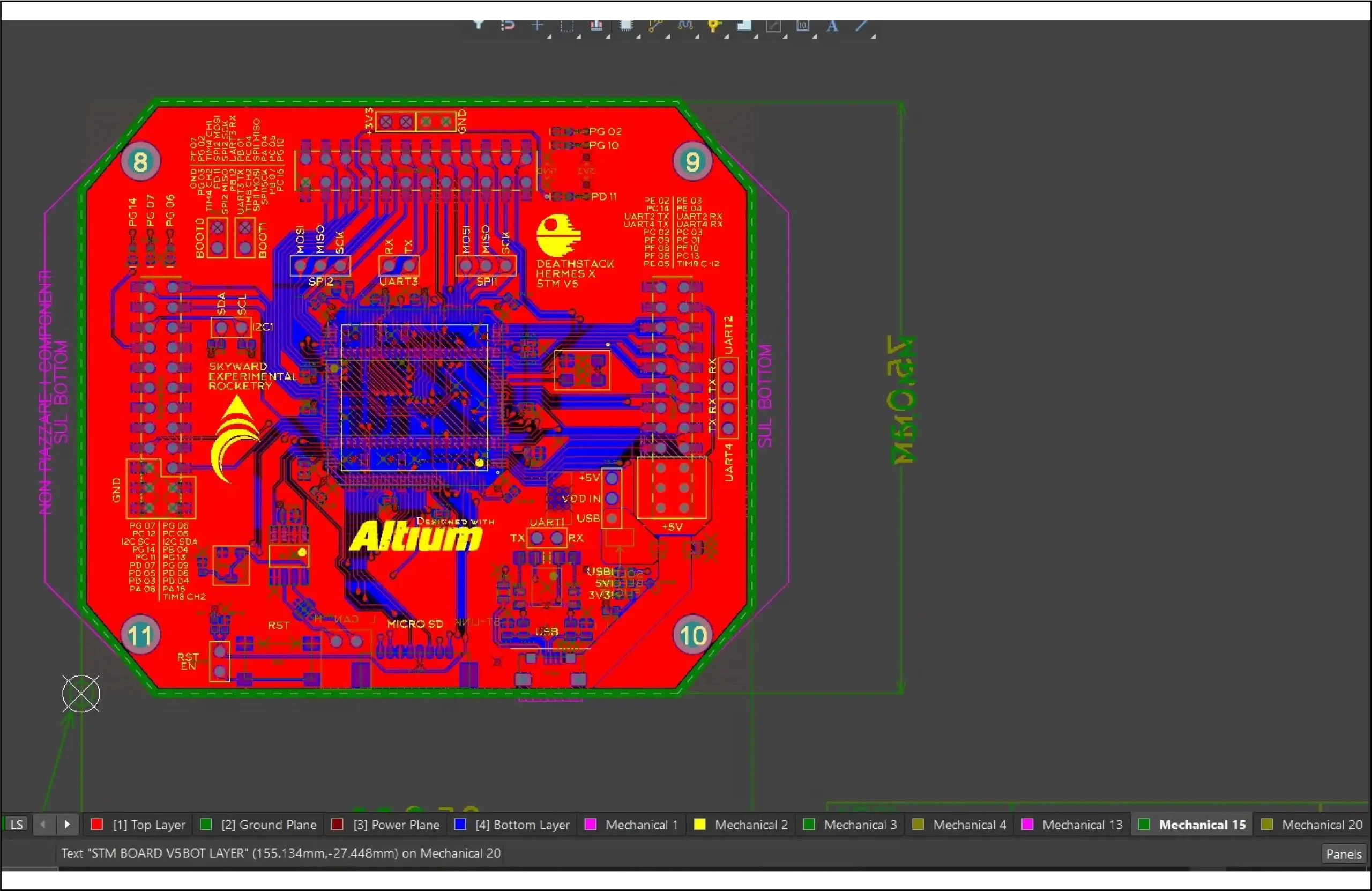

Electronic Computer Aided Design (ECAD)

The next natural step is the employment of ECAD softwares to design our circuits, and once the schematics have been confirmed we determine that all connections between the components are correct. In that case we proceed with the realization of the PCBs (Printed Circuit Boards), which are a physical application of the schematics, by connecting all components on the board following a topology that has been optimized to reduce the size and improve reliability, while also meeting the design requirements of the other departments.

Fast Prototyping and testing

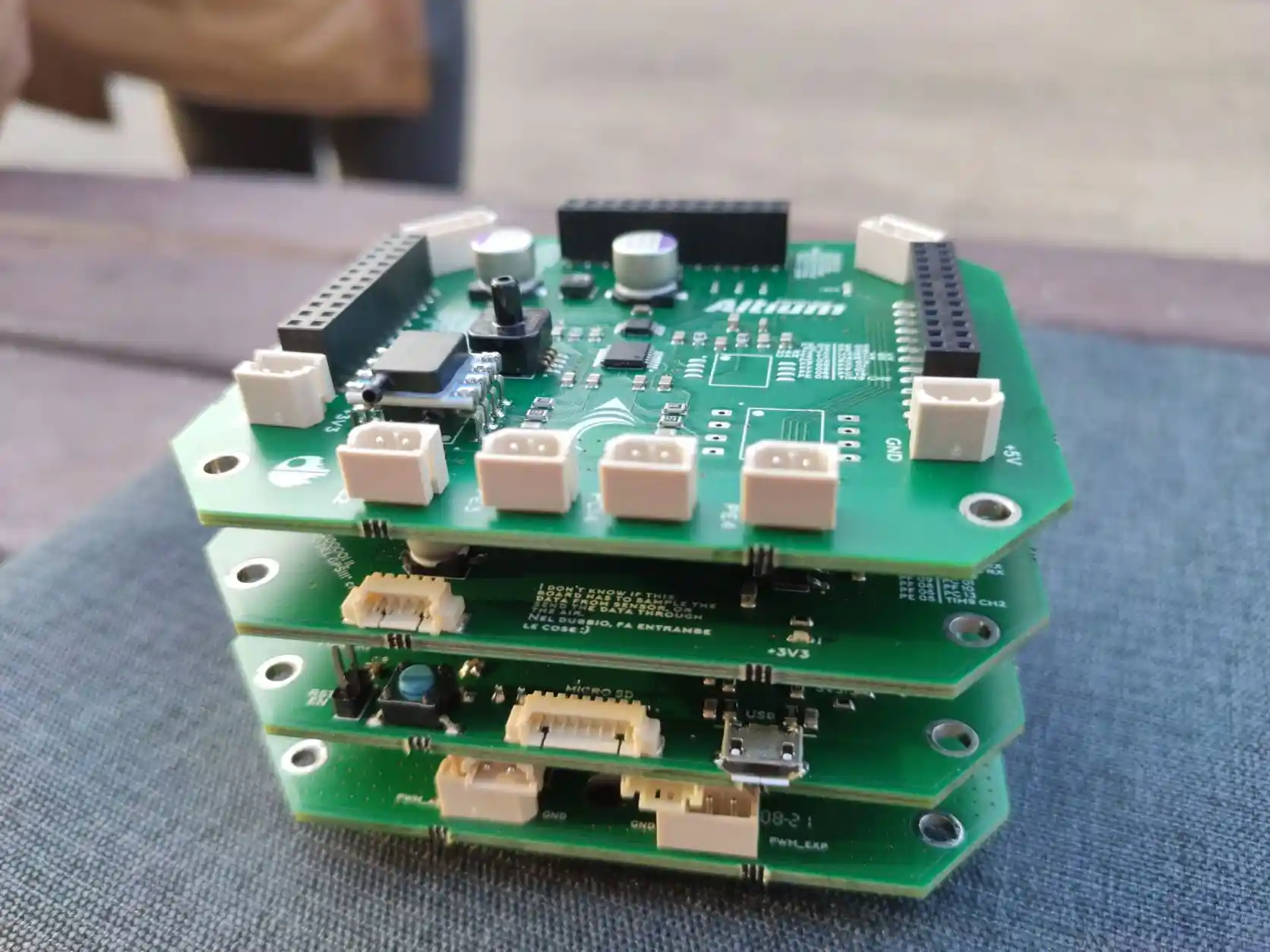

After confirming all our PCBs design, the production phase begins. If the adopted solution is simple enough we proceed by fabricating it by ourselves, though the majority of the time we rely on our unselfish sponsors who industrially manufacture it under our specifications.

Once the board is ready we solder all components on it, which are mainly SMD in order to reduce both the size and cost of our PCBs. Soldering is not a fast paced activity, as precision and accuracy are of the utmost importance to ensure that each component is placed correctly!

Finally, we thoroughly test the fully assembled boards to determine whether our final design meets all our imposed criteria to be implemented on board the rocket.