Structural Design and Sizing

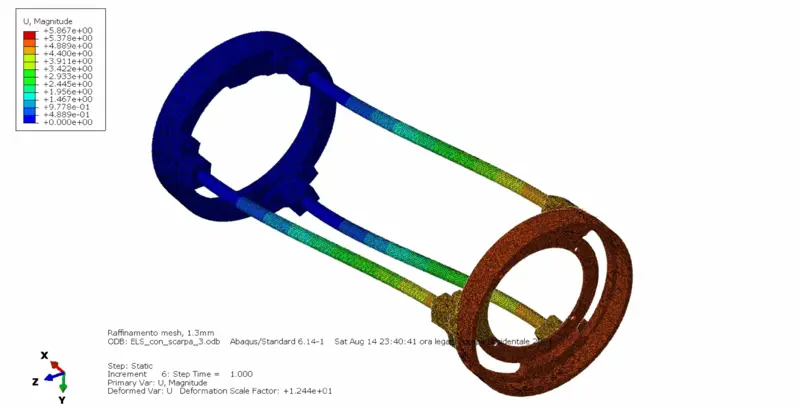

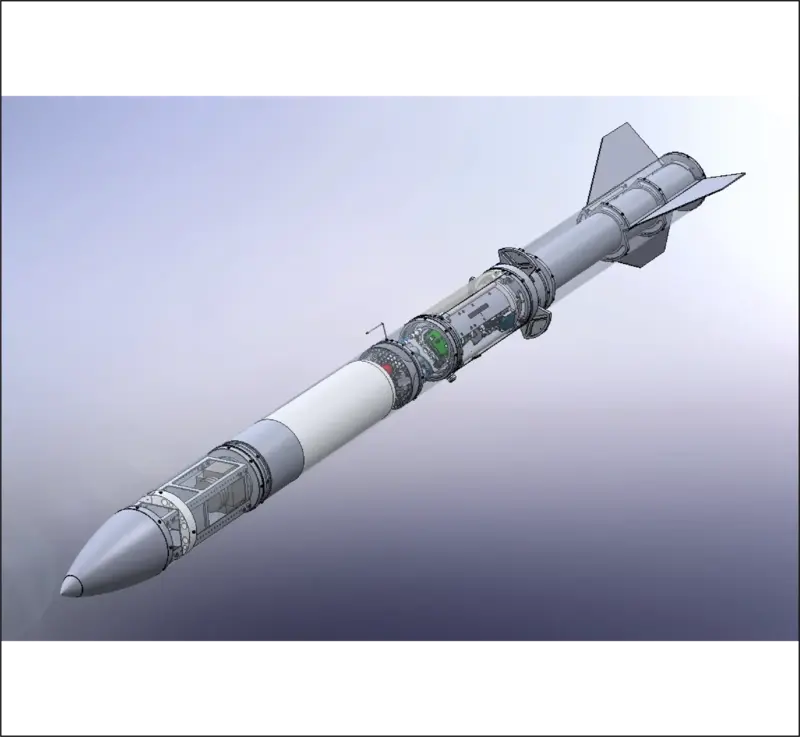

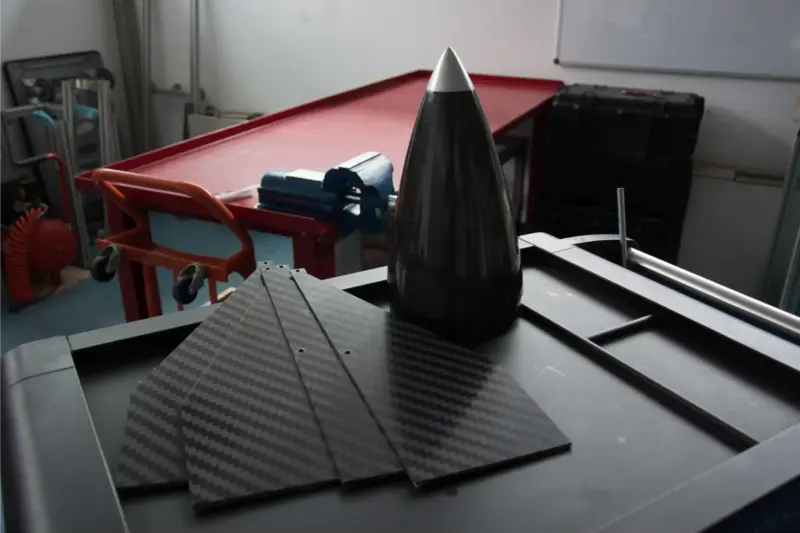

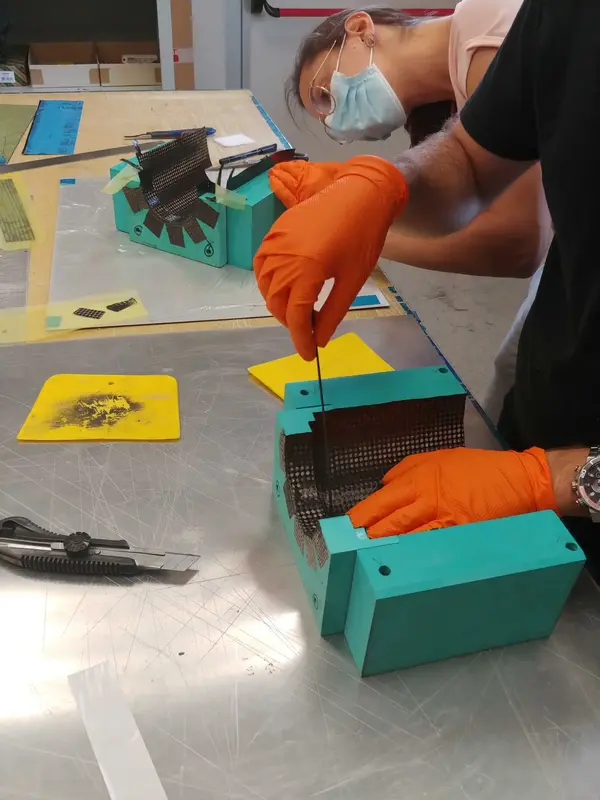

Every great rocket begins with a solid idea and solid structures. Our work starts by defining the constraints each component must withstand during flight: speed, pressure, vibrations, and more. From initial sketches to detailed 3D models, we shape every part using CAD software, in close collaboration with other departments to ensure that form and function go hand in hand. Once the overall structure is defined, we move to optimization—where the real engineering challenge begins. Using Finite Element Analysis, we simulate the most extreme conditions the rocket might face and refine each piece by removing any excess material, keeping only what’s essential for strength and safety. It's a balance of precision, creativity, and purpose. Because behind every bolt and flange, there's the drive to build something that can rise above the Earth—and the passion of a team turning ideas into flight.