Design

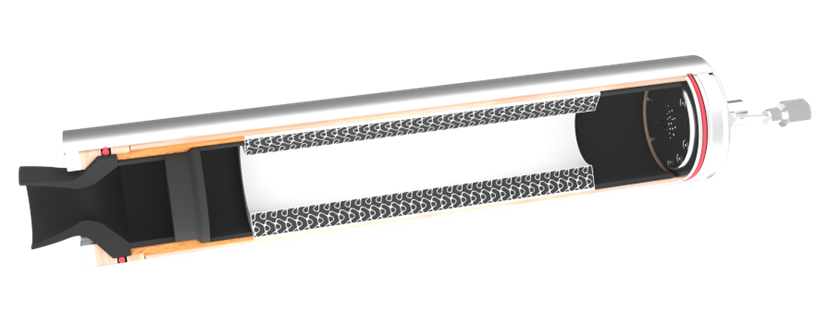

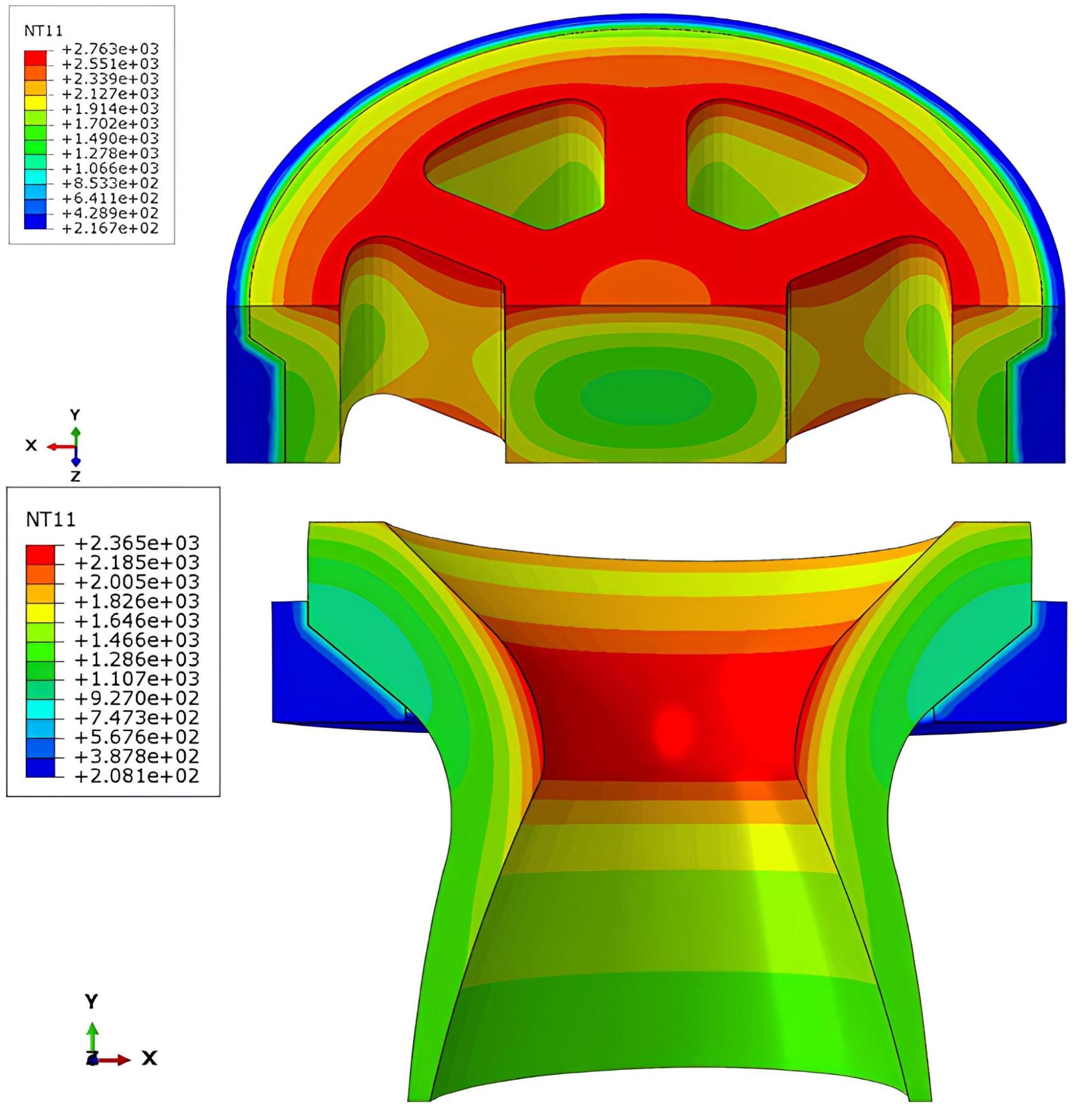

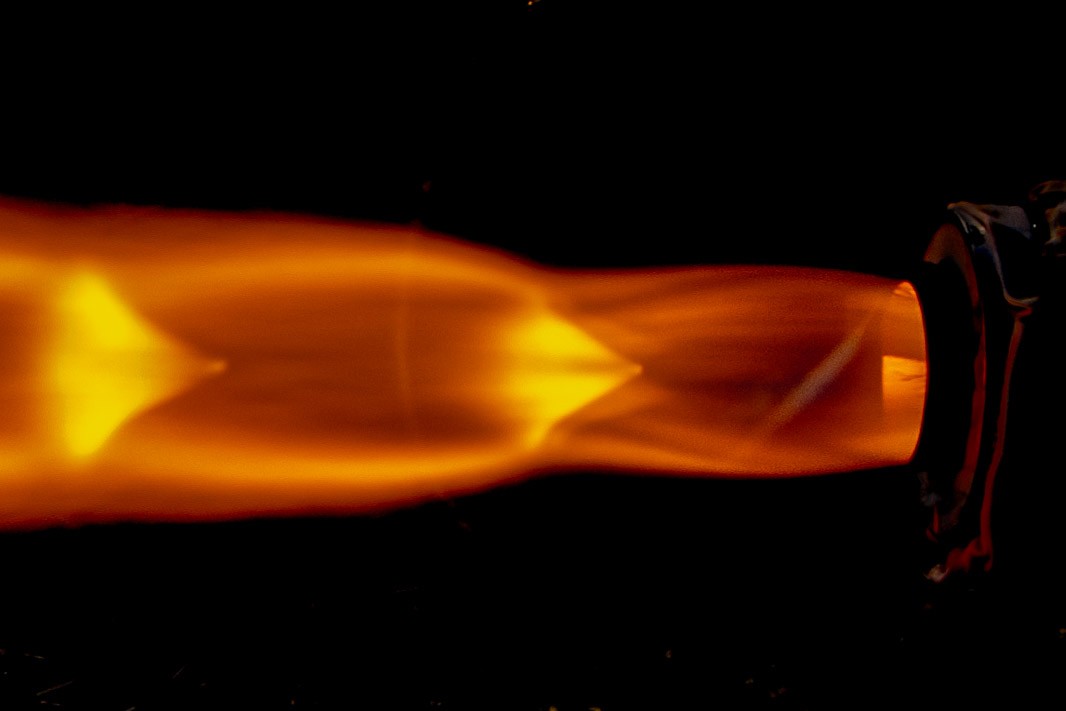

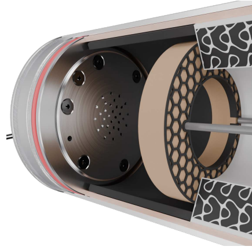

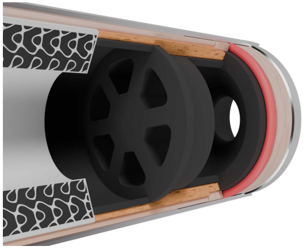

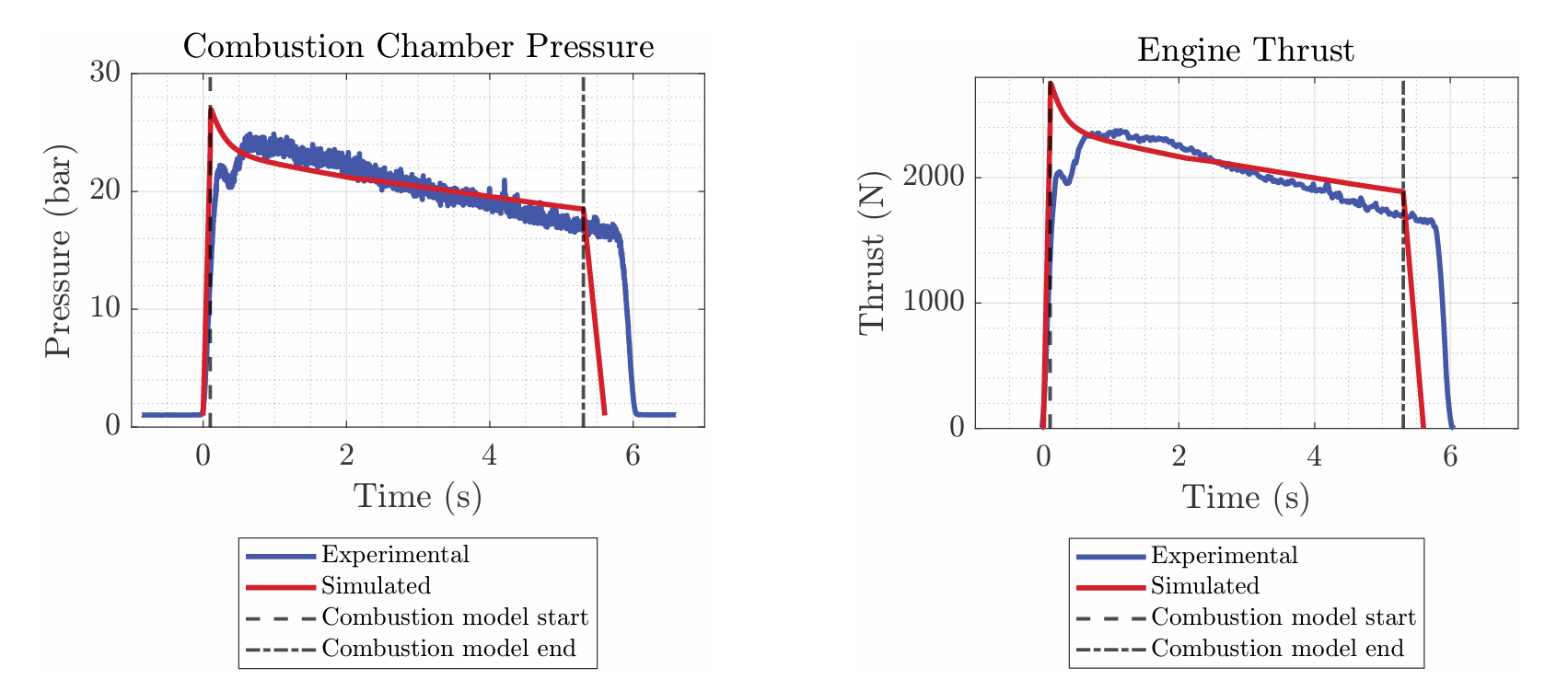

The design phase begins with defining the mission requirements and performance goals of the engine. Based on these, we perform preliminary calculations and choose the appropriate engine configuration. We then carry out thermomechanical analyses to size the components and ensure their mechanical integrity. Custom simulation tools help us model combustion behavior, heat transfer, and overall engine performance. The design is iteratively refined through analytical results, simulations, and feedback from testing.