Preliminary Design

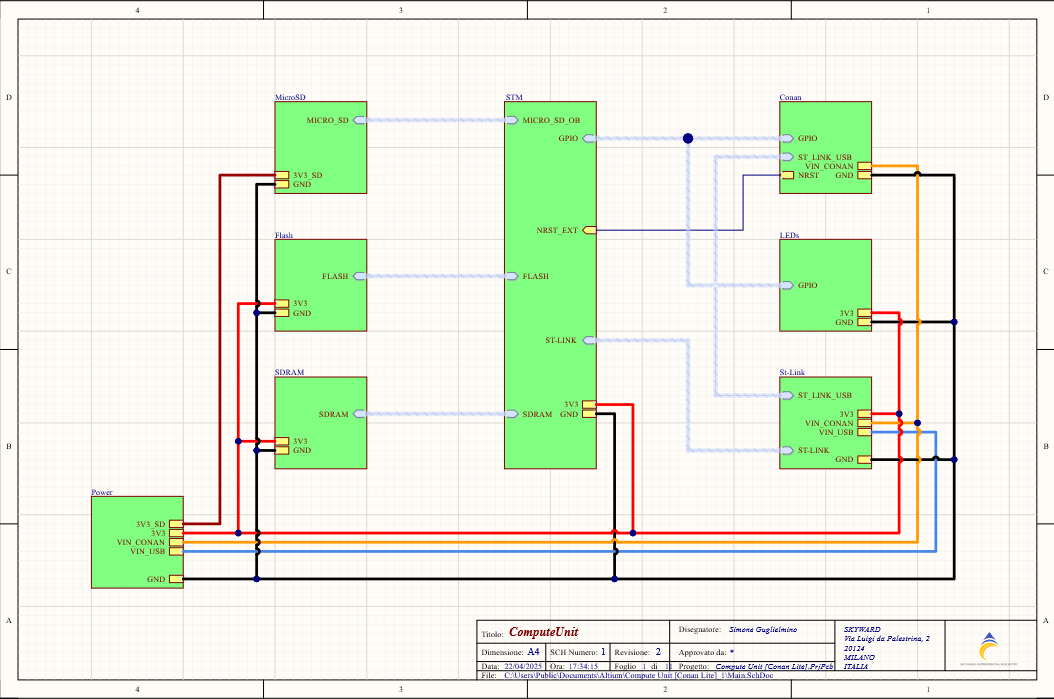

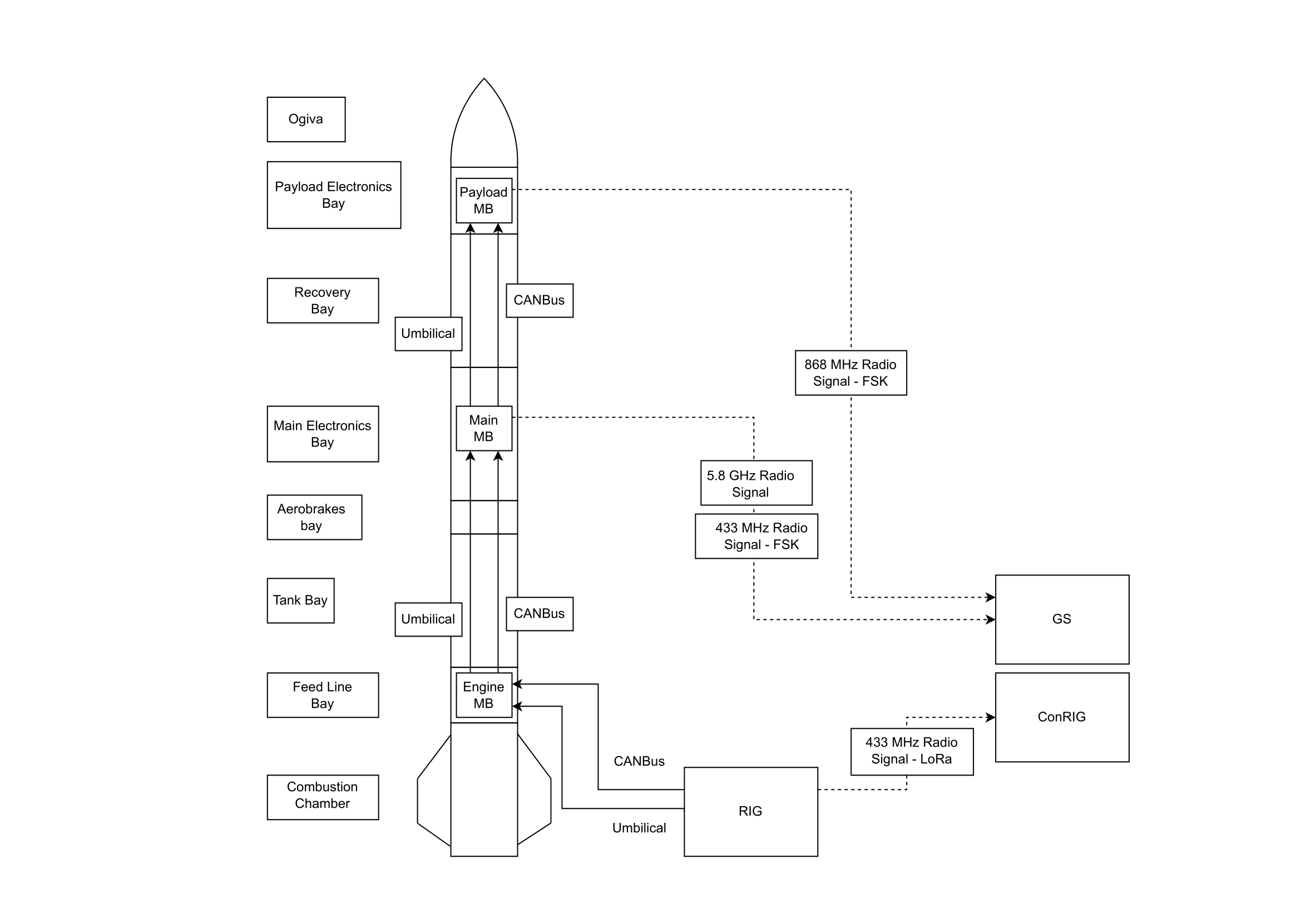

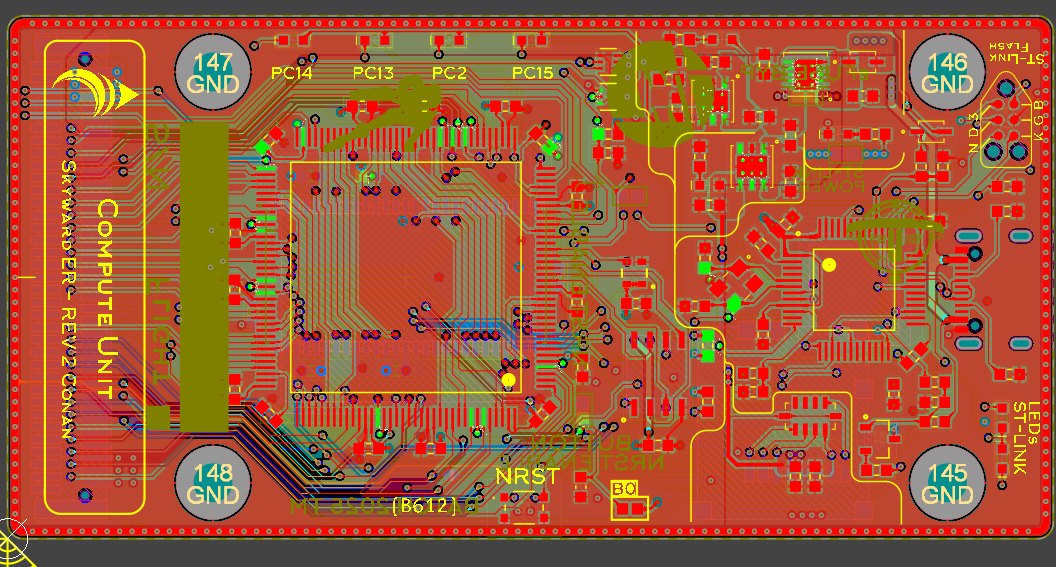

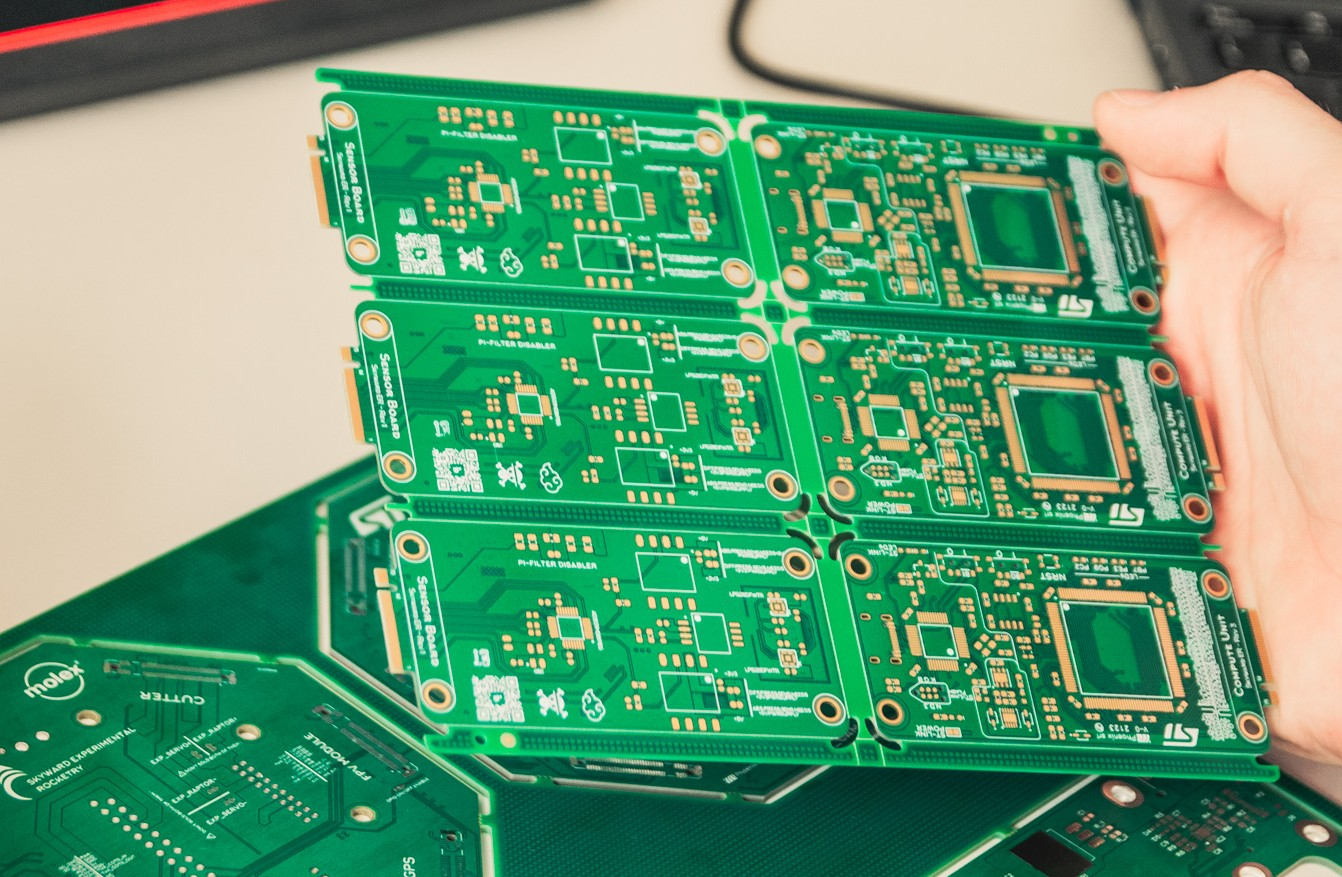

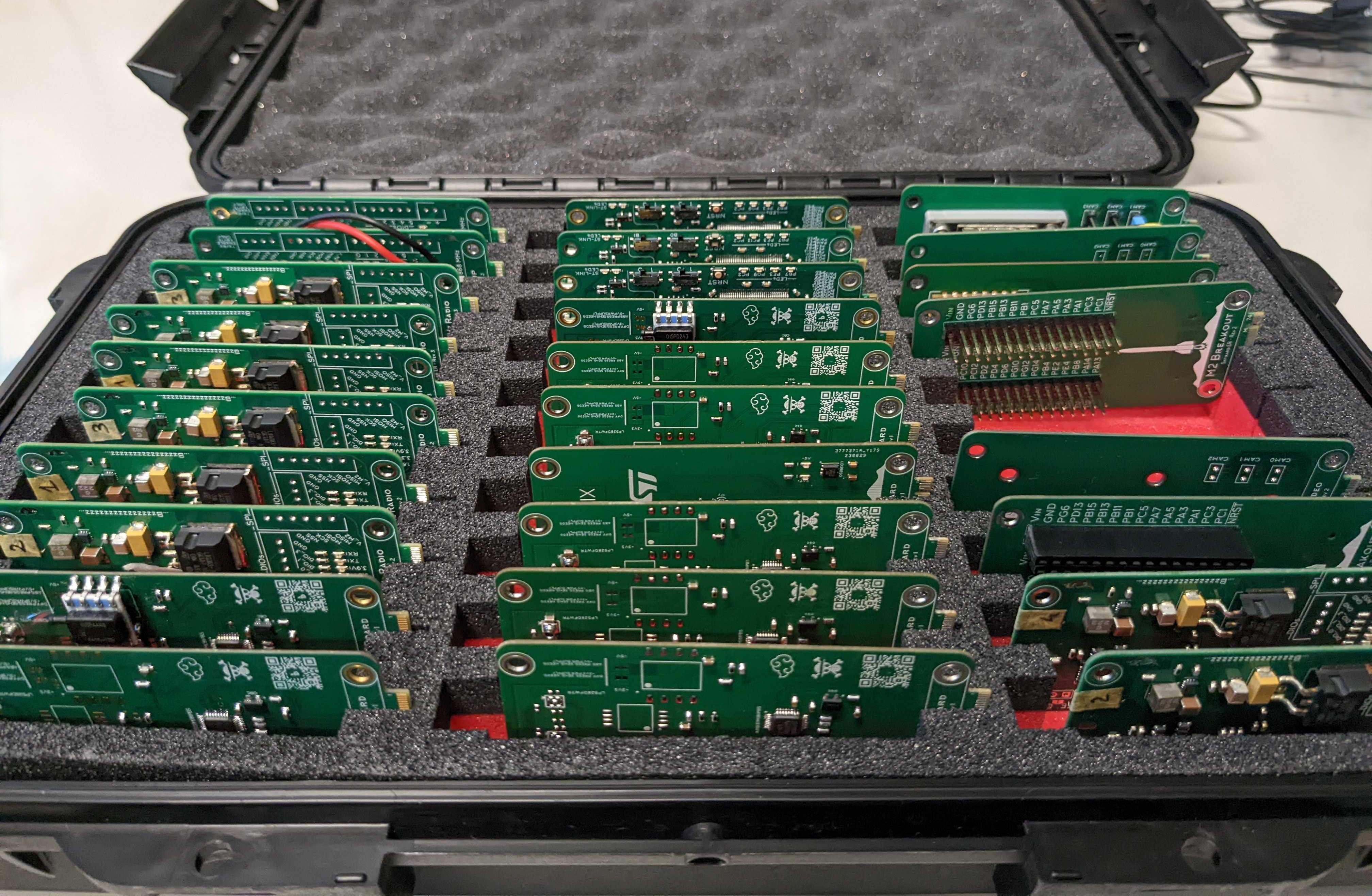

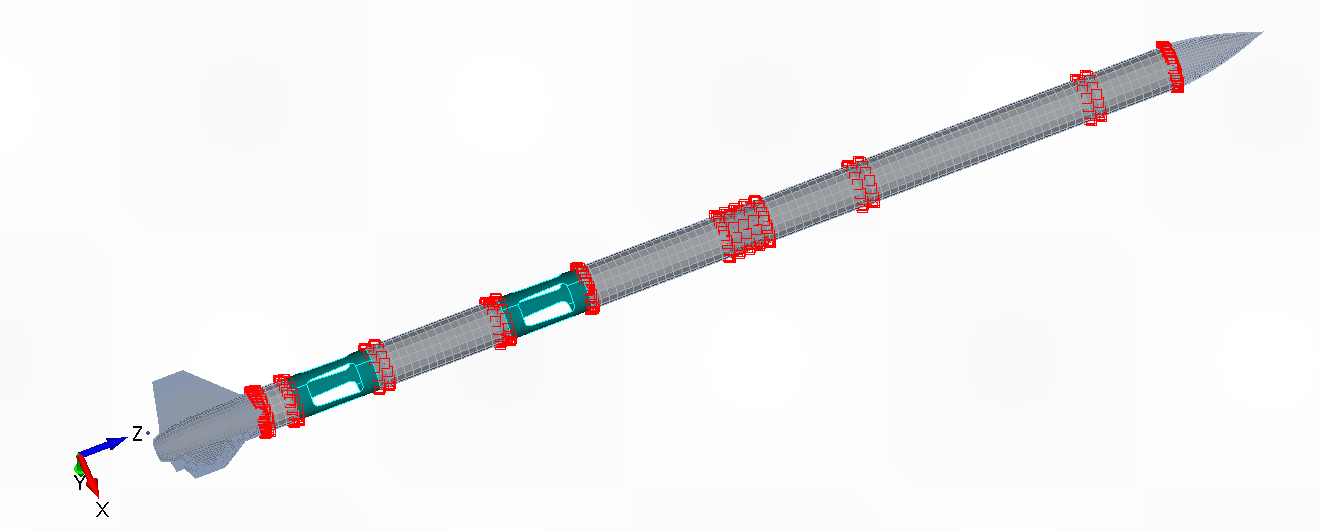

The electronics system is developed from the earliest phases of the project. Starting from requirements such as space constraints, computational needs, data acquisition, and actuation, the team defines the system architecture and prepares for PCB design. An initial analysis includes estimating the power budget, the number of supported sensors and actuators and the connection with every subsystem. These results are then shared with other departments to ensure alignment across the entire mission design.