Composite Design

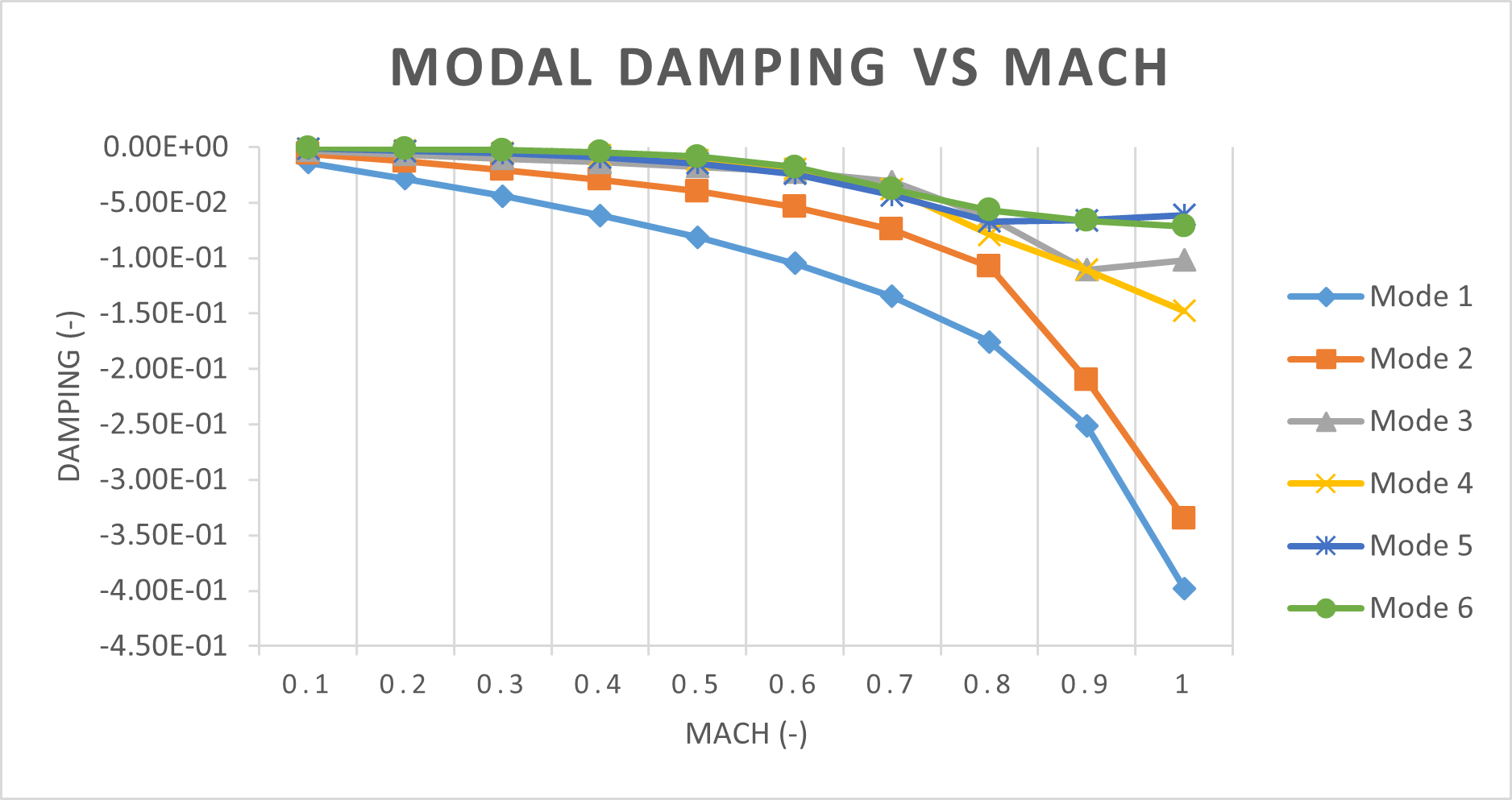

We conduct CFD simulations across a spectrum of boundary conditions that represent various flight parameters, including velocity, pressure, and altitude. We examine different flight scenarios, such as steady-state flows, and consider both compressible and incompressible regimes, as well as subsonic and supersonic speeds. Additionally, our team performs plume simulations to analyze the behavior of motor exhaust and its interaction with external airflow, essential for understanding the overall aerodynamic performance. Upon completing the simulations, we evaluate convergence and perform detailed post-processing to extract aerodynamic coefficients, pressure distributions, and flow visualizations.