Æneas

The First Italian Liquid Engine built by Students

Overview

Æneas is a demo-prototype Liquid Rocket Engine, developed and built entirely by Skyward, with the aim of studying the liquid propulsion field. After an initial feasibility study and a design phase of the engine, production kicked off in February 2024, with tests beginning in May. As a demonstrative project, Aeneas focuses on the rapid development of a safe and reliable engine, without fixed performance requirements. The design leverages on Skyward’s knowledge of working with N2O as an oxidizer, gained through the work on hybrid engines and introduces the use of ethanol as a liquid propellant, with N2 serving as a pressurizer.

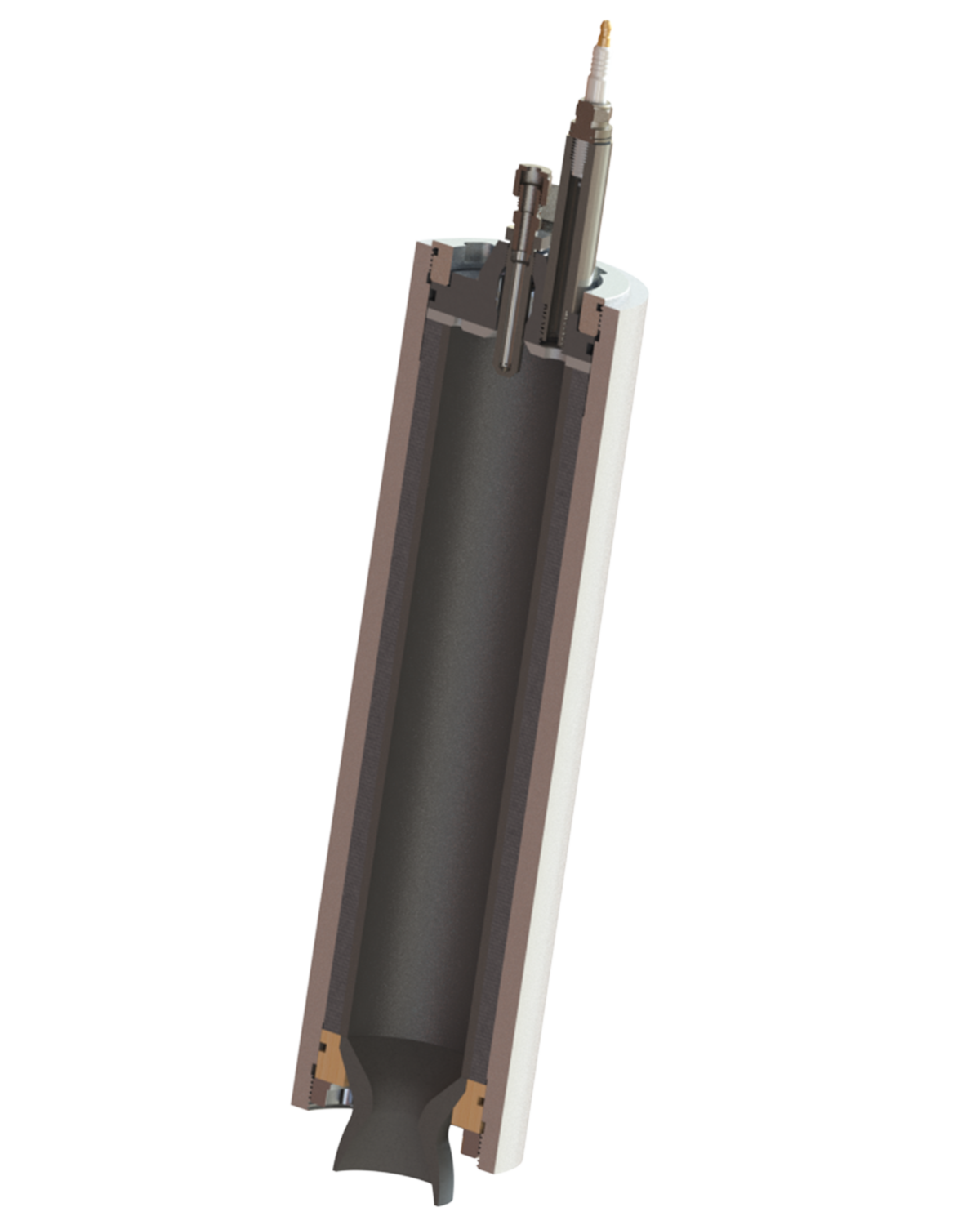

Combustion Chamber

The combustion chamber features an aluminum housing derived from the same raw material as Furia, Gemini’s engine, with an internal diameter fixed at 80mm. The chamber is insulated with a graphite fabric, and the nozzle is also made of graphite, with a design similar to the one used in last year’s project. A wedge of laminated fabric is used to support the nozzle, ensuring stability and performance under high-stress conditions.

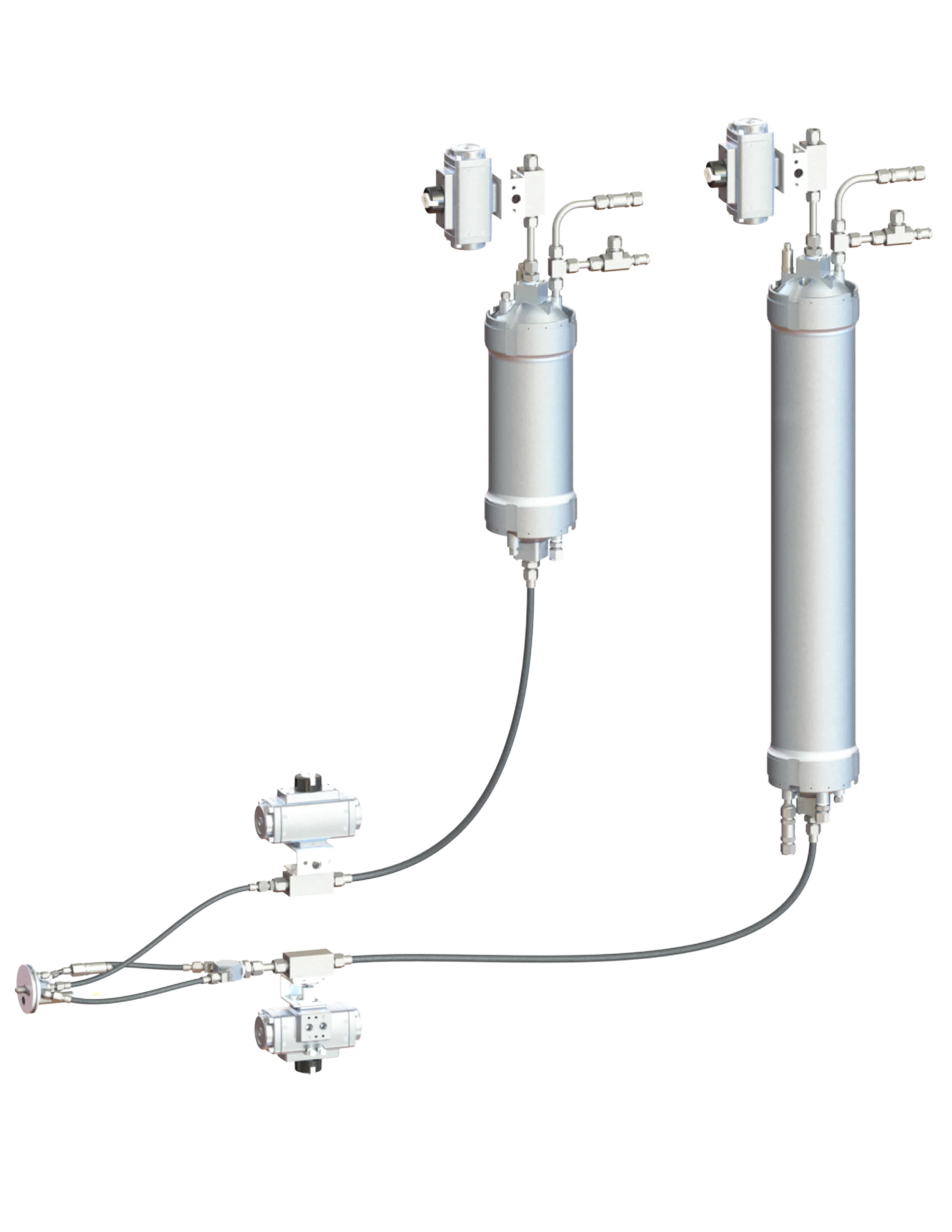

Tank and Feed Line

Our feed system repurposes tanks from the Gemini project to store the two propellants – ethanol and nitrous oxide (N2O). Nitrogen is used as a pressurizer, contained in a commercial vessel and regulated in the two tanks through pressure regulators. The feedline has a completely new design, featuring 1/2″ lines for both oxidizer and fuel, controlled through the use of pneumatic valves, enhancing reliability and easing operations.

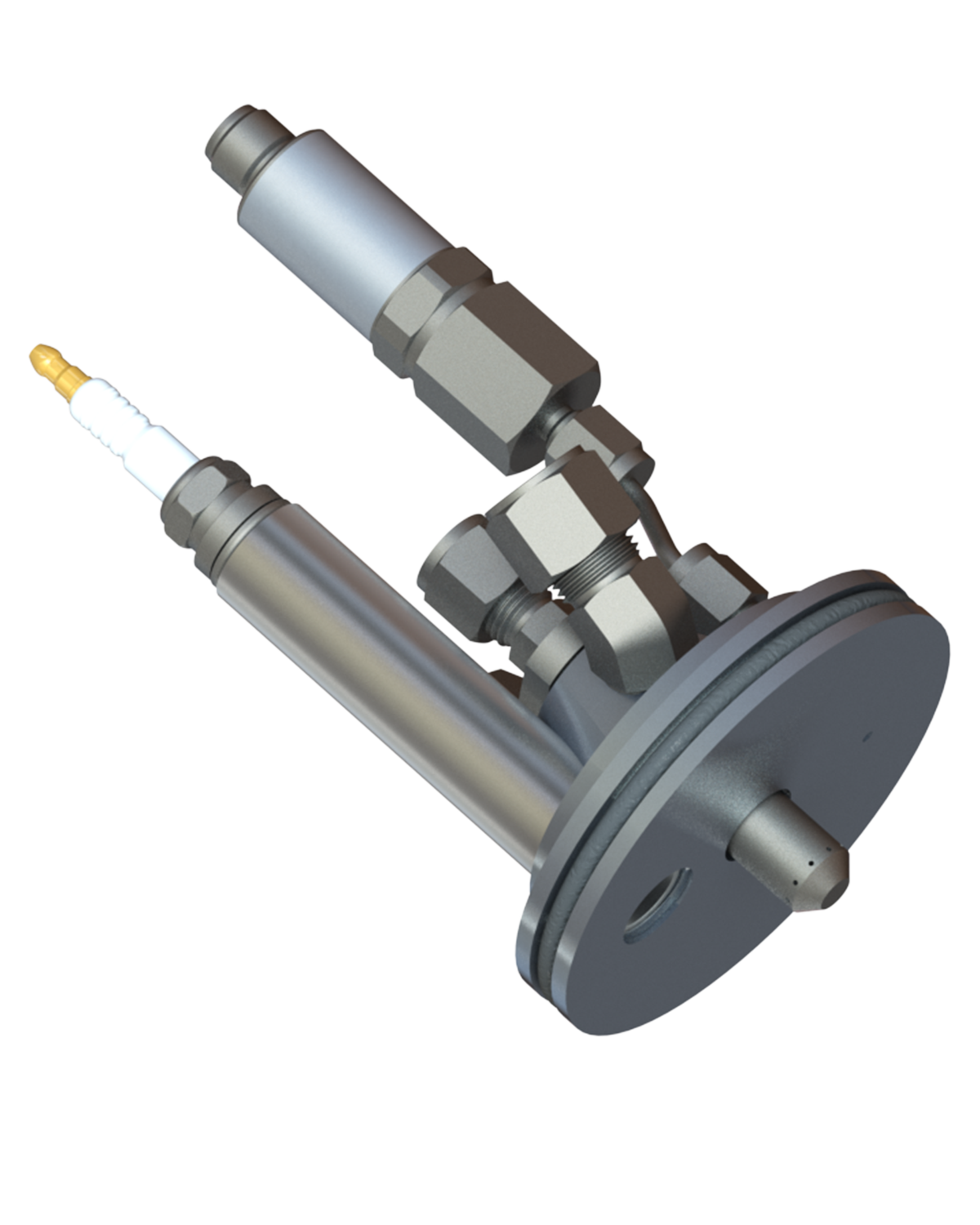

injection subsystem

For an efficient combustion, our engine uses a pintle injection system: this injects a thin film of oxidizer axially through an annular hole, while the fuel is injected all around, through radial holes. This setup ensures that the fuel impacts the oxidizer while being injected, allowing atomization and guaranteeing a high combustion efficiency. The injection head also includes two ports for a transducer, measuring combustion chamber pressure, and the ignition system.

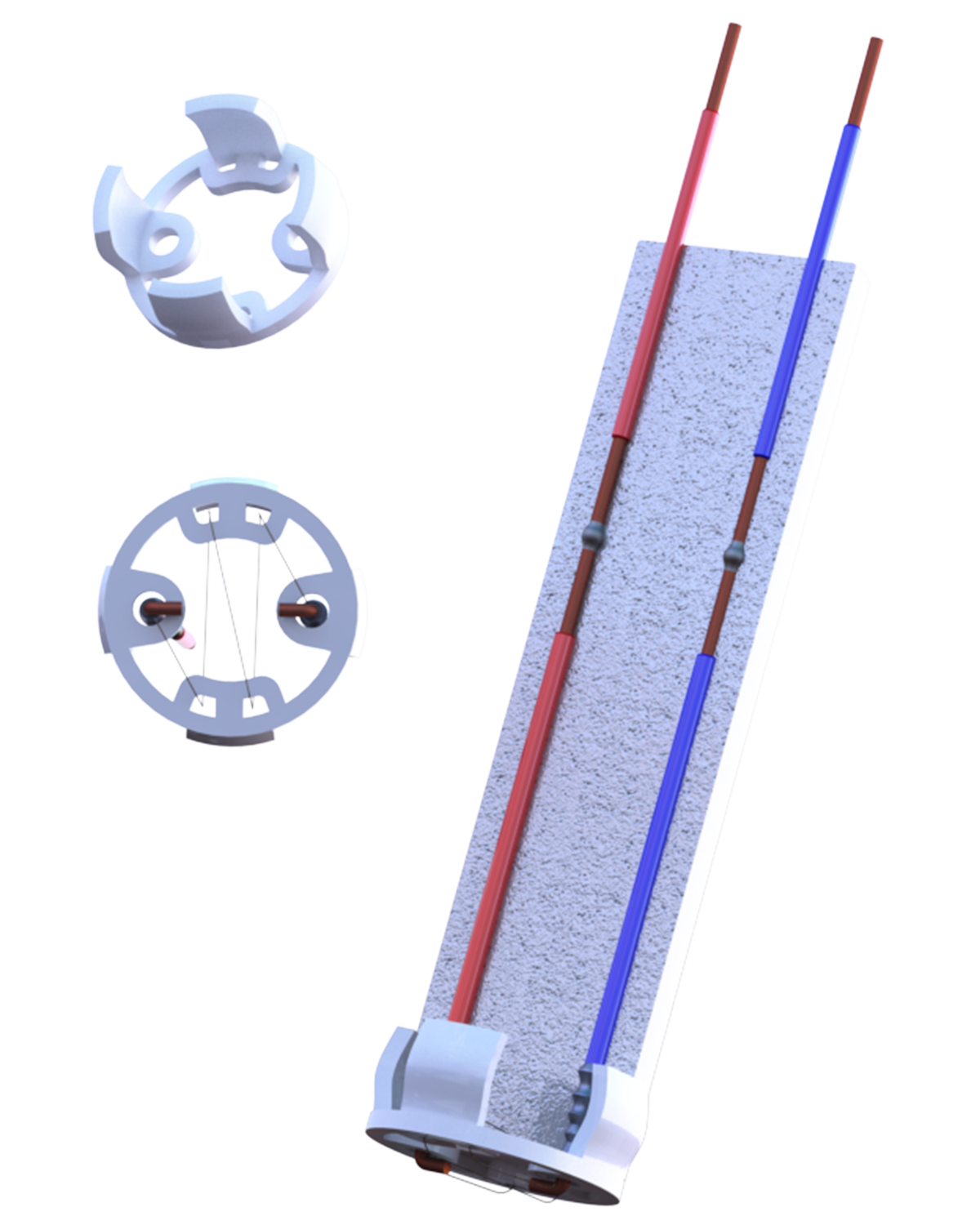

Ignition Subsystem

The ignition subsystem consists of an “end-burning” rocket candy cylinder, ignited by a nickel-chrome wire, which heats up to initiate combustion. The igniter includes a circuit capable of detecting successful ignition. This subsystem has undergone extensive research and testing to ensure its reliability and characterization.